We develop and realize with you

Innovative tooling systems for the industrialization of composite component manufacturing.

From the development of new manufacturing technologies to the realization of complete production systems and commissioning, ALPEX Technologies offers total solutions for the efficient production of composite components for a wide range of high-performance applications. Our main industries are Aerospace, Automotive, Defence Space.

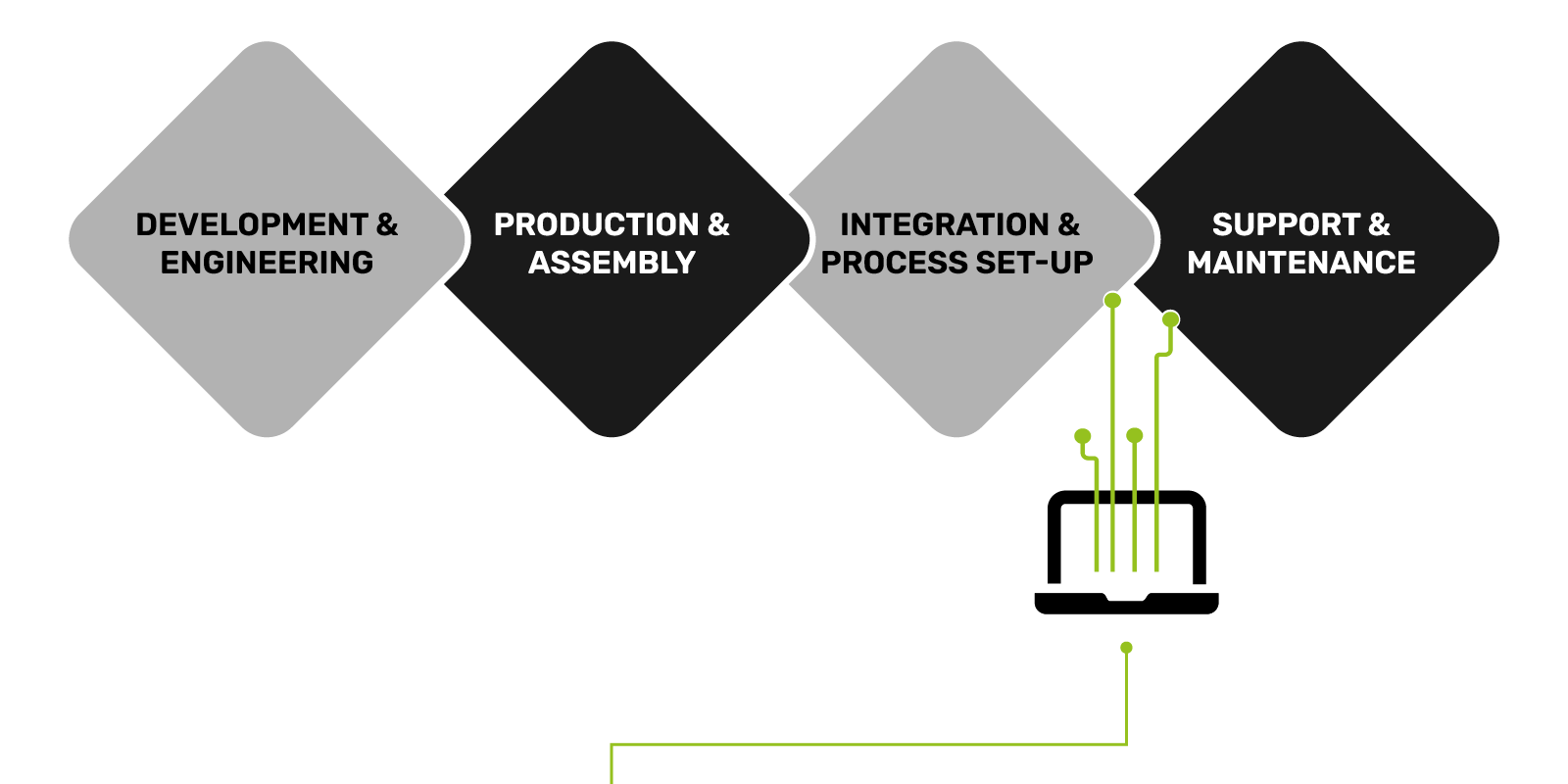

The entire range of services in the house

Development manufacturing expertise

Our promise of quality

ALPEX Business Excellence

you will find our SOLUTIONS all over the world

ALPEX Tooling Systems – Reference projects

LARGE SCALE AEROSPACE RTM

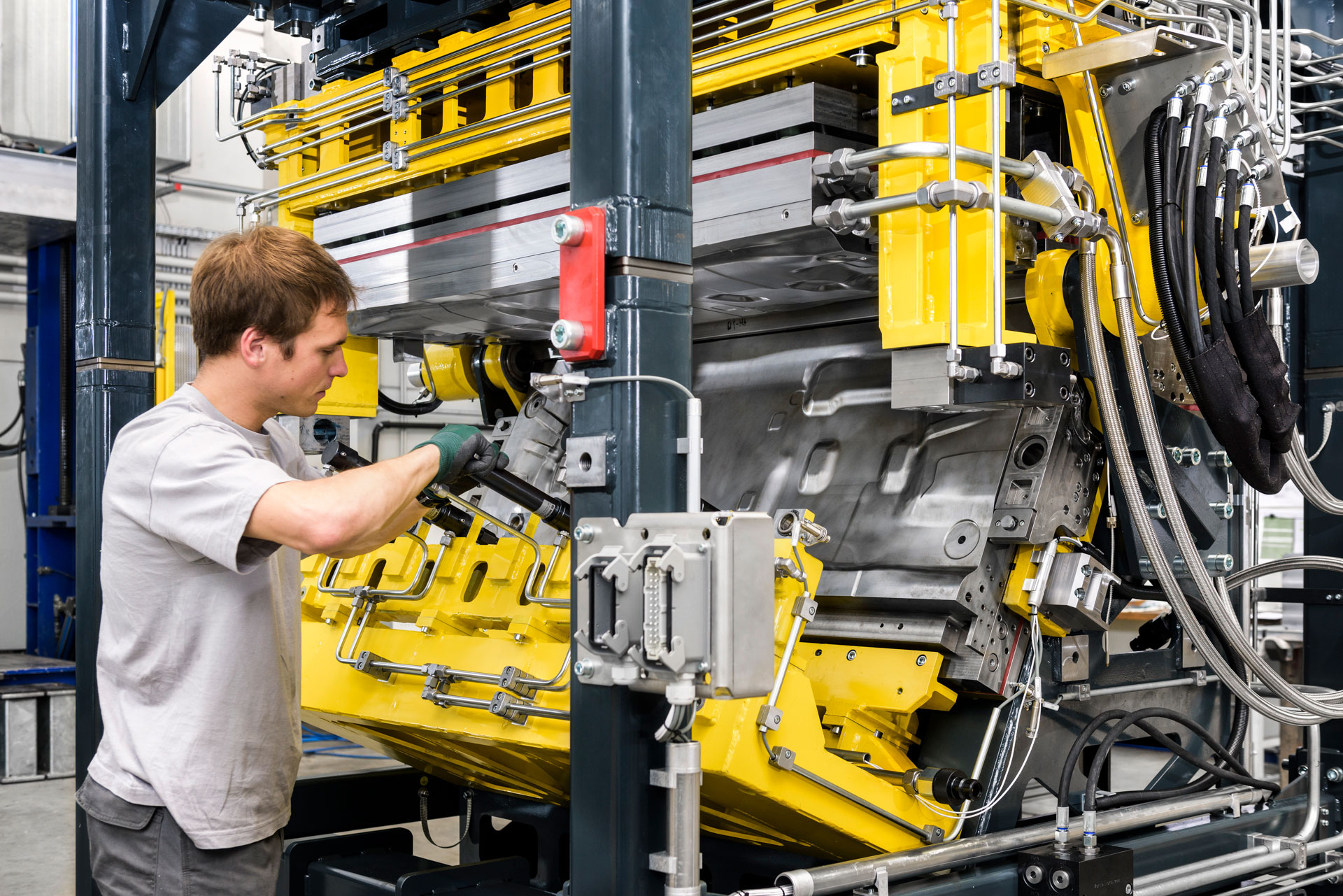

RTM PRODUCTION

RTM PRODUCTION

SYSTEM

INNOVATION

Automated one-shot production of large & complex integral CFRP structures

CUSTOMER BENEFIT

Overall manufacturing cost reduction

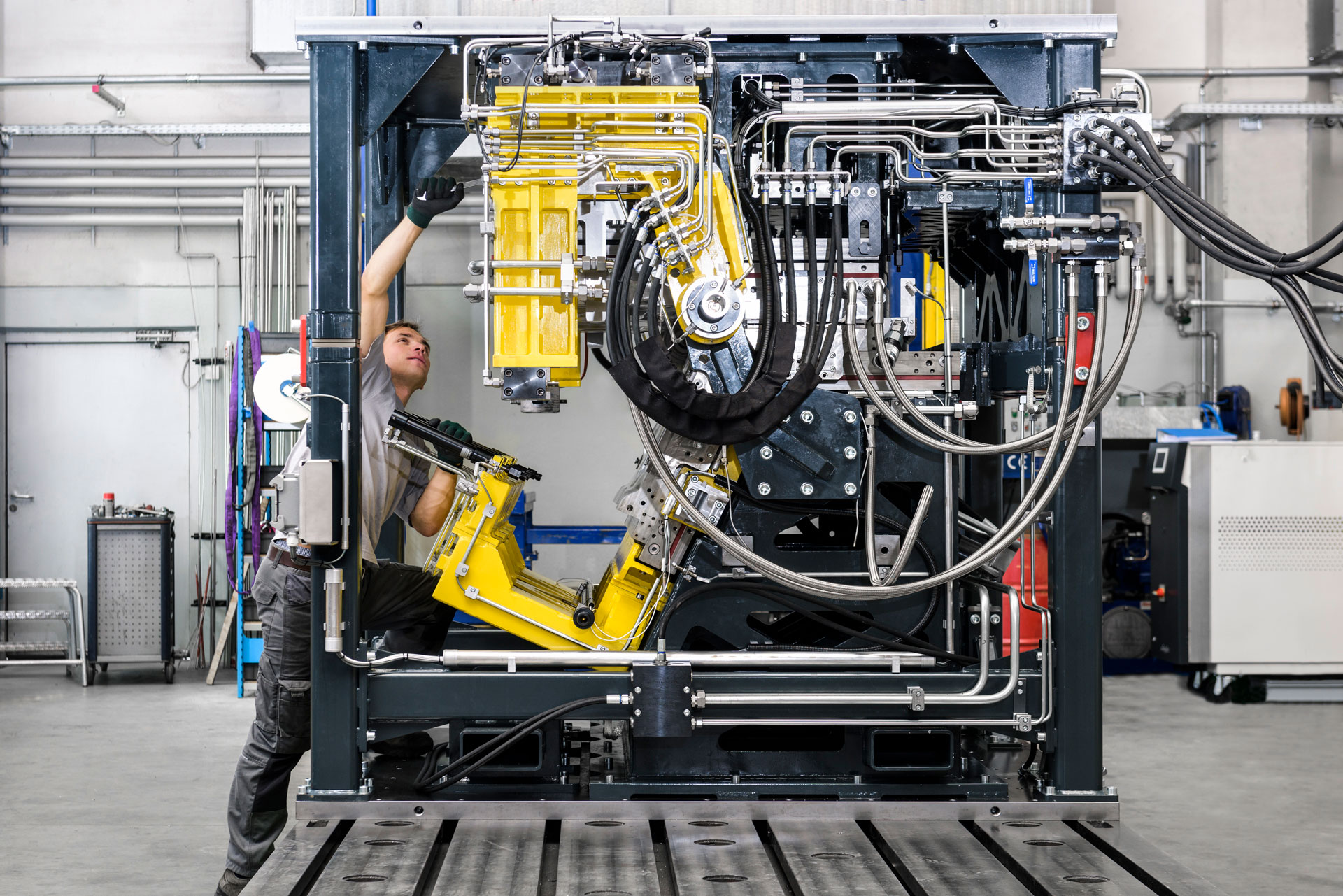

STANDALONE CLOSED MOLD RTM

RTM PRODUCTION

RTM PRODUCTION

SYSTEM

INNOVATION

First RTM Tool for Aerospace applications

CUSTOMER BENEFIT

Technology transfer from Automotive – Automated production process

LAYUP TOOL & INVAR CURING TOOL

CFRP WING

INNOVATION

Large modular INVAR curing tools with special sealing / welding technology

CUSTOMER BENEFIT

Custom tooling technologies developed for Advanced one-shot resin infusion process

CFRP LEAF SPRING

MULTI-CAVITY HP-RTM SYSTEM

INNOVATION

Advanced high rate HP-RTM tooling technology

CUSTOMER BENEFIT

Automated HP-RTM production system for industrialized GFRP Leaf Spring serial manufacturing

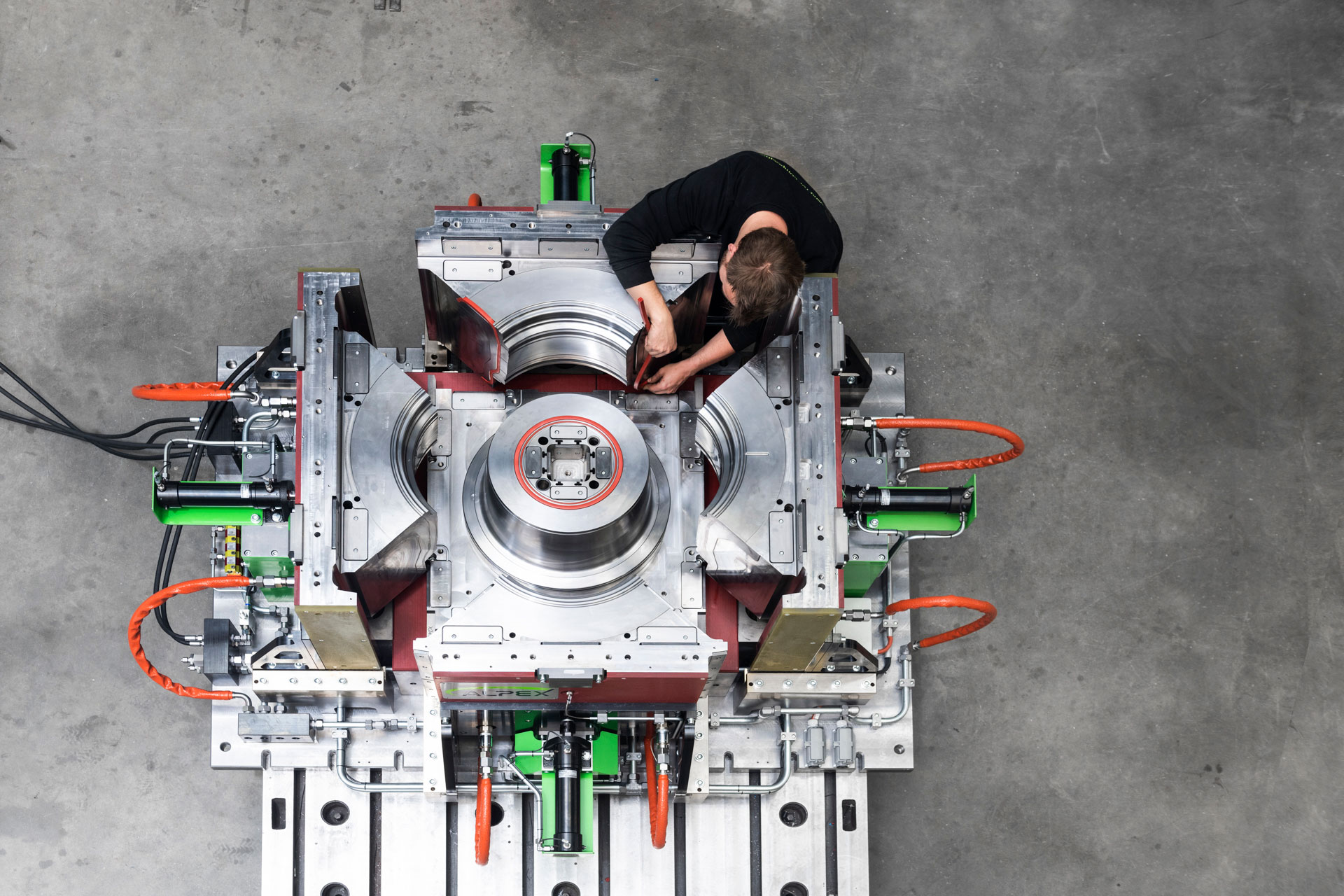

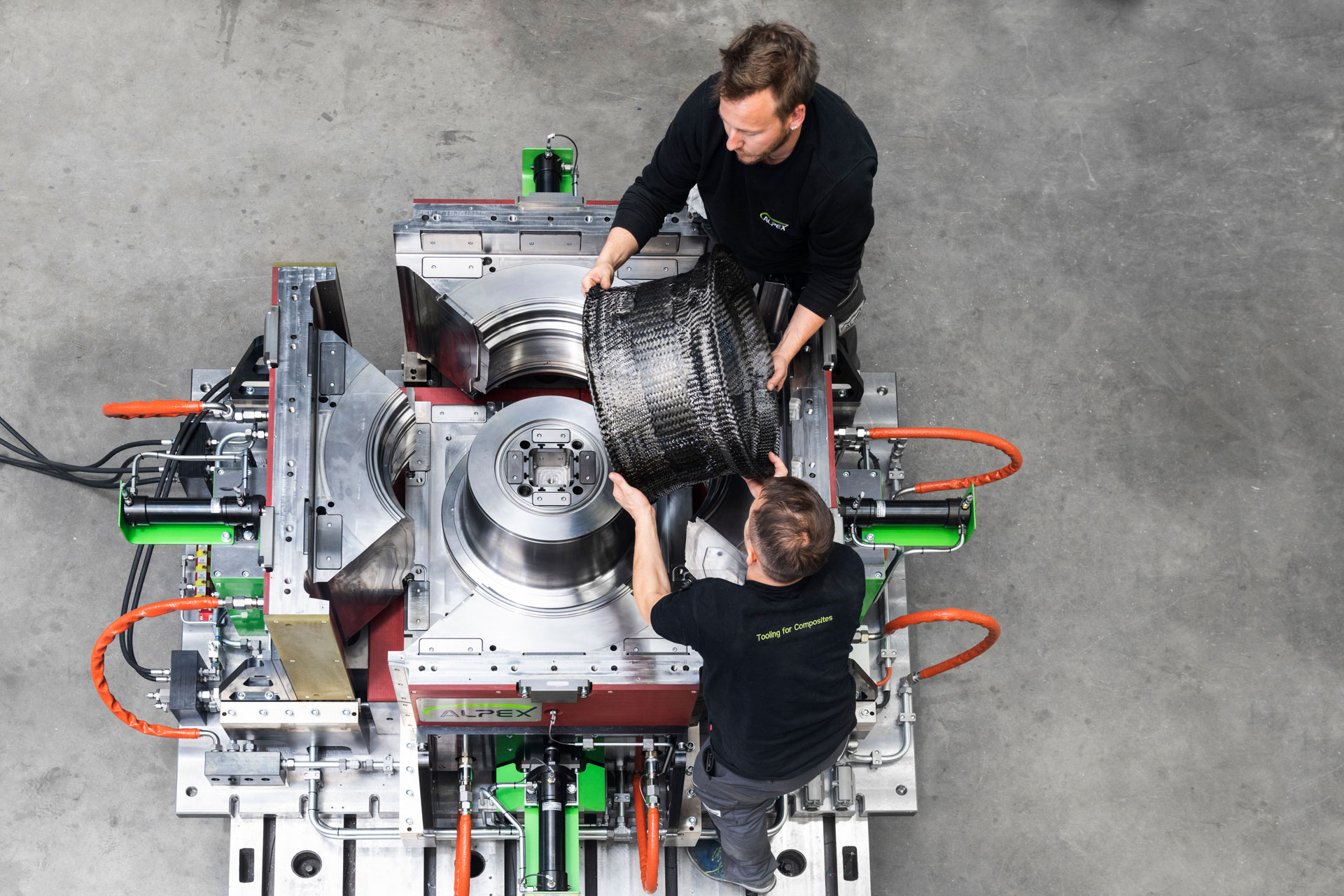

CFRP HYBRID WHEEL

HP-RTM TOOL WITH SLIDERS

INNOVATION

Advanced slider technology for composite wheel production

CUSTOMER BENEFIT

High rate HP-RTM capability

MECHATRONIC SYSTEMS

AUTOMATED

OPERATING

EQUIPMENT

FOR INDUSTRIAL

APPLICATIONS

INNOVATION

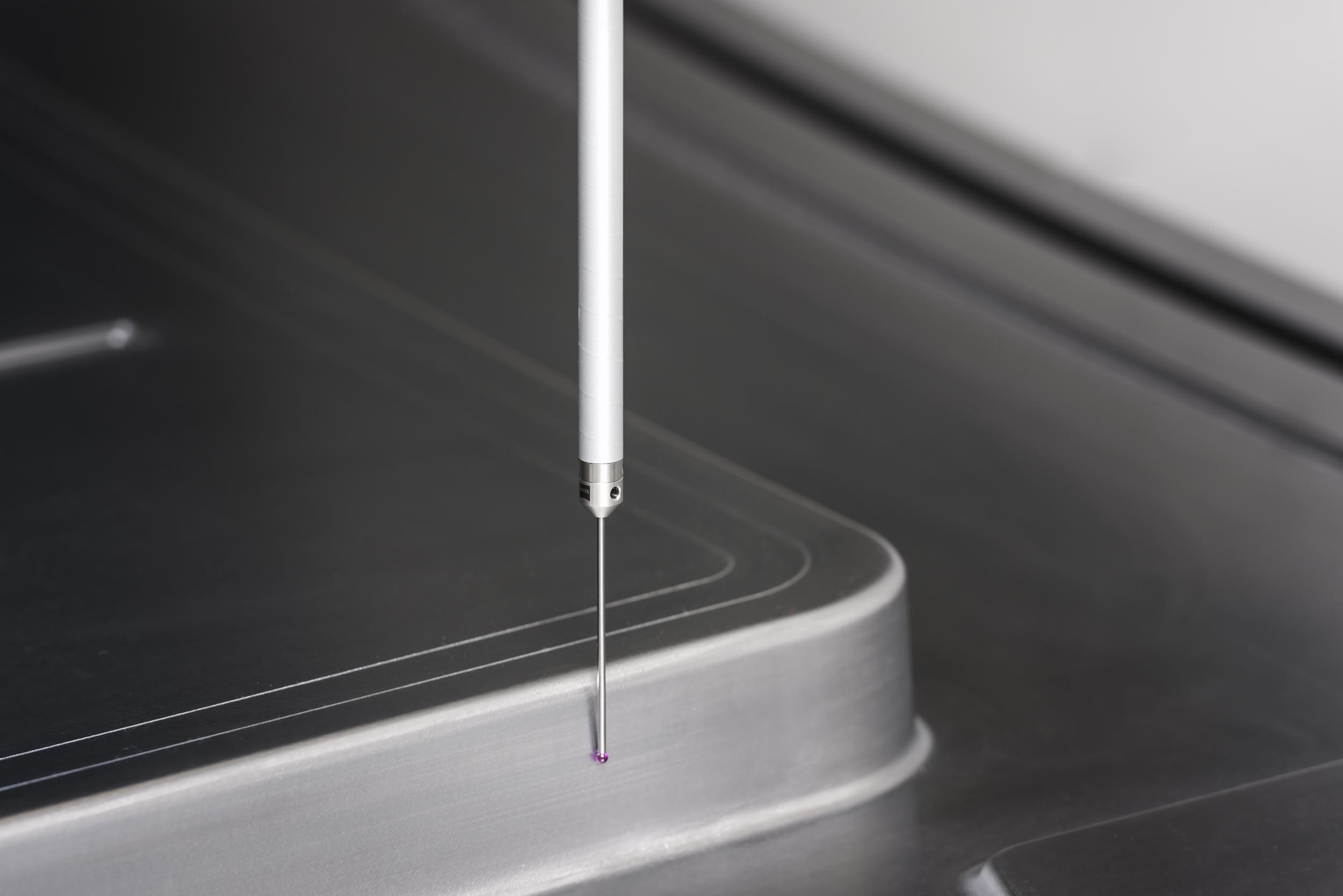

High precision and quality with several axis movements on heavy metal parts for clean room applications

Accessibility and versatile operation on large scale, heavy equipment

CUSTOMER BENEFIT

Ergonomic usage

High reproducibility

Automated process setup